how is nano hardness testing conducted|nanohardness dental material : export Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material. 7 de dez. de 2023 · F# gives you simplicity and succinctness like Python with correctness, robustness and performance beyond C# or Java. F# is open source, cross-platform and free to use with professional tooling. F# is a JavaScript and .NET language for web, cloud, data-science, apps and more.

{plog:ftitle_list}

WEBAction Games. Our free online action games include classic 2D platform games, cartoony adventures, and a range of strategy and 3D titles. Have fun playing hundreds of the best action games for free. Sort by 'most played' for the most popular action games.

Nanoindentation Test. Precision load-displacement curves are offered by a nanoindentation test for performing tests on both soft and hard surfaces as well as rough surfaces, such as those deposited by industrial .Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material.Nanohardness testing refers to hardness tests wherein the depth of indentation usually is less than about 50nm or equivalently, the indentation diameter/length is lower than about 150nm. . The nano-indentation test is used for non-destructive characterization and analysis of the mechanical properties of materials at the nano scale. In this method, an indenter with .

Indentation technique evaluates the mechanical properties of materials by driving an indenter into the material surface and subsequently imaging the impression. Indentation .

Nanohardness testing is eminently suited for measuring the hardness of thin films/coatings (thickness of coatings <1 μm), the hardness of micro-constituents like fibers and particulates .

microhardness test. Through the analysis of the loading–unloading curve, not only hardness and elastic modulus can be obtained, but also information such as vis-coelasticity, creeping, . Nanoindentation is an effective approach in which a defined indenter tip is forced into a specified spot in the test sample, increasing force is applied, and gradual unloading is conducted until the required depth is achieved.

Nanoindentation is a method for testing the hardness and related mechanical properties of materials, facilitated by high-precision instrumentation in the nanometer scale, as .Hardness test methods use an indenter probe that is displaced into a surface under a specific load. In traditional testing, the size or depth of indentation is measured to determine hardness leading to user bias in the data.KLA offers the Nano Indenter® G200, a nano hardness tester that also performs scratch, wear and indentation testing. US (English) Mainland China (简体中文) Taiwan (繁體中文) . The Express Test option is a novel, fast way to .

2.2.1 Oliver and Pharr Method (O&P Method). O&P method is the most widely used model in nanoindentation technique. Typical indentation load–displacement curve and indentation profile before and after unloading process are shown in Figs. 2.1 and 2.2, respectively [].As the indenter is driven into the material, elastic deformation firstly occurs on the surface of . To measure nanomechanical properties of surface layers of bulk materials and thin films, depth-sensing nanoindentation measurement techniques are used commonly. The nanoindentation apparatus continuously monitors the load and the position of the indenter relative to the surface of the specimen (depth of an indent or displacement) during the indentation .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .

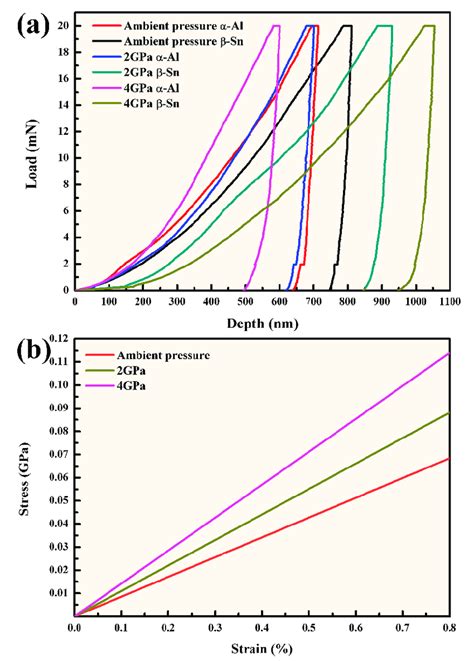

The micro/nano indentation hardness of single crystal aluminium and single crystal silicon are investigated. Load–depth curves can be obtained by nanoindentation instrument, and materials indentation hardness can be calculated by Oliver–Pharr method and work of indentation method directly from these curves. The hardness that obtained by Oliver–Pharr .Nanoindentation is vital for revealing the quantitative mechanical properties of small volumes of materials. Currently, this method is a standardized method for determining plastic, elastic, and visco-elastic properties of materials such as ceramics, biological materials hard thin films, soft films, multi-phase metals, semiconductors, and plastics on a micron to nanometer scale.

Generally, hardness testing can be conducted on a wide range of materials, but there are exceptions where it’s not feasible. For instance, the material must be solid, or at least have a gel-like consistency. Even among solid materials, certain factors like highly irregular surfaces or non-homogeneity can impede accurate hardness testing. .

The hardness usually defined as the ratio of P max to project area of hardness impression A c (Eq. (1)), and perhaps the most widely used method is Oliver–Pharr method [3]. (1) H op = P max A c The Oliver–Pharr method analysis procedure begins by fitting the unloading curve to an empirical power-law relation [3], [7]. (2) P = α (h − h r) m where P is the indentation .

Microhardness testing can be defined as indentation hardness testing that involves . (Vickers), three-sided pyramid (Berkovich) and asymmetric pyramid (Knoop). Berkovich tips are used mostly for nano-indentation (discussed in Section 2.5) and the others . Microhardness testing is easy to conduct and can be carried out using ASTM E384 . For example, Lu et al. [6] conducted nano-indentation experiments on the C-plane of sapphire with Berkovich indenter and found that the hardness was 29.3 GPa when the indentation depth was 90.1 nm. . The hardness (H) of the test surface is determined using Eq. (1) developed by Oliver and Pharr [35]. The contact area can be described in Eq.

compression test chevy 305

Furthermore, Bose et al. (2015a) were able to test the fly ash particles for their size, nano-hardness, reduced elastic modulus, and fluid loss prevention as well as for their induced fracture . With a nano-indenter and a microhardness testing machine, nano-indentation hardness and microhardness are measured in a wide load range (0.1–19600 mN) for five materials.

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion .Nano-indentation tests measure hardness by indenting using very small indentation forces (of the order of 1 nano Newton) and measuring the depth of the indention which is made. . Brinell hardness test was one of the most widely . Nano- and micro-indentation testing of sintered UO 2 fuel pellets with . nanoindentation and microindentation testings were conducted on SPS-sintered UO 2 with controlled stoichiometry and grain size. Hardness and Young's modulus at three different temperatures were evaluated during nanoindentation testing, while hardness and fracture .Ceramic Pro nano-technology has been proven by independent rigorous testing by SGS. The world's leading independent testing and certification entity. . Hardness by Pencil Test (500g), Alkali Resistance, Acid Resistance, Salt .

Nanoindentation test is similar as a microscale hardness test. The modulus and hardness at each indentation point can be calculated based on the recorded load-displacement curve. . (Keysight Nano Indenter G200) was conducted on the polished surfaces of the shale samples. Further triaxial compression tests were conducted on the same polished .Practice of Micro Flexible Rolling. Zhengyi Jiang, . Haibo Xie, in Microforming Technology, 2017. 15.2.3.2 Hardness Test. A Vickers hardness testing machine was employed to determine the hardness differences of all the rolled strip specimens in the thicker, thinner, and transition zones by applying a load of 1 N with a dwelling time of 12 s. Hardness measurements were .Experimentation of Micro-Vickers Hardness Test for Composite Nano Materials using DoE 1 Preethi K., 2 Dr. Raju N.T. 1 USN : 1DA15PMJ07, . Experiments are being conducted and the results are obtained w.r.t. some of the material properties such as the hardness test evaluation of the materialistic property. The results show

hardness using a hard steel ball as the indenter.6 Then, several other hardness tests have been developed, including the Rockwell, Vickers, Knoop, and Berkovich tests, and different shapes of indenters have been adopted.7–11 ASTM standards have been developed for testing hardness and materials parameters of different materials.3,12 Hardness .

what is nano hardness

nanoindentation hardness testing in structural alloys. We selected . nanoindentation testing was conducted at a constant strain rate. of 0.05/s. . issue in nano- and micro-indentation research .The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test force >= 49.03 N), more precisely with a test force of 29.42 to 1471 N. It is a differential-depth method. The estimated errors of the mean values of hardness and elastic modulus obtained from the nano-indentation test were 26.8 and 48.5 percent compared to the micro- and macro-scale tests .

compression test chevy 350 engine

Nanoindentation testing was then conducted on the treated shales to characterize their hardness, Young’s modulus, and fracture toughness to examine the alteration of shale’s mechanical .

For decades, nanoindentation has been used for measuring mechanical properties of films with the widely used assumption that if the indentation depth does not exceed 10% of the film thickness, the substrate influence is negligible. The 10% rule was originally deduced for much thicker metallic films on steel substrates and involved only the hardness measurement. Thus, . A greater m/f hardness ratio indicates a higher degree of strain partitioning to the softer ferrite phase, potentially inducing more damage to the matrix (shear bands, initial voids, etc.). Thus, a higher m/f hardness ratio will likely produce a sheared zone with greater ferrite damage before hole expansion testing, resulting in a lower HER.

compression test chevy silverado

compression test chevy silverado 2500

compression test chiropractic

O identificador de fuso horário IANA para Inglaterra é Europe/London. domingo março 31 2024. Next change: Summer time starts. Switching to UTC +1 / British Summer Time .

how is nano hardness testing conducted|nanohardness dental material